Features of Universal Laser Systems (ULS) cutting and engraving machines

- lucymcnaughton

- Jan 6

- 4 min read

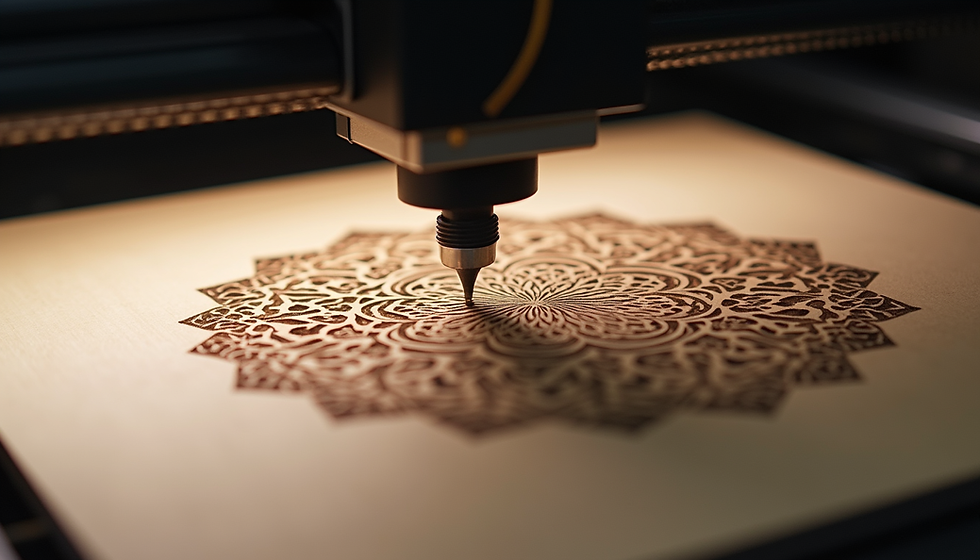

When it comes to precision, efficiency, and versatility, laser cutting machines have become indispensable tools across various fields. Whether you are working on architectural models, crafting intricate designs, or producing educational materials, having the right laser cutting machine can make all the difference. Today, I want to share insights into the features of Universal Laser cutting and engraving machines that set them apart and why they are a smart investment for your projects.

Why choose Universal?

ULS laser cutting machines offer a level of accuracy and speed that traditional cutting tools simply cannot match. They use a focused laser beam to cut or engrave materials with incredible precision. This technology is ideal for working with a wide range of materials such as wood, acrylic, fabric, paper, and even metals.

One of the biggest advantages is the ability to create complex shapes and detailed designs without the need for physical tools that wear out or require frequent replacement. This not only saves time but also reduces material waste, making laser cutting an eco-friendly option.

Moreover, laser cutting machines are highly adaptable. You can switch between cutting and engraving modes, adjust power settings, and change the speed to suit different materials and thicknesses. This flexibility is especially useful for educational institutions and creative professionals who work on diverse projects.

Key features of Universal Lasers

Universal Lasers laser cutting and engraving machines are known for their robust build quality and advanced technology. Here are some of the standout features you can expect:

1. Precision and accuracy

One of the most important features is the precision these machines offer. ULS (Universal Lasers) focus on delivering machines that can cut with tolerances as fine as 0.1mm. This level of accuracy is crucial for architectural models and detailed craftwork where every millimetre counts.

The Universal Control Panel (UCP) and the Laser System Manager (LSM) are user interfaces that control ULS laser systems. Both user interfaces are configured intuitively, enabling all users to produce expert quality results. Both include a Printer Driver and Direct Import Feature for uploading graphic designs. They also provide an Intelligent Materials Database that calculates optimised settings for laser processing on hundreds of materials. The printer driver supports various file formats like SVG, DXF, and AI, making it easy to import designs from popular graphic design programs. This is particularly helpful for beginners and educational users who may not have extensive CAD experience.

3. Versatile material compatibility

Universal machines are designed to handle a broad spectrum of materials. From thin paper and fabric to thicker acrylic sheets and even some metals, ULS systems provide the flexibility needed for diverse applications. This versatility is a huge plus for crafters and architects who often work with multiple materials.

4. Rapid Reconfiguration™

Universal Laser Systems is the only laser system manufacturer that offers Rapid Reconfiguration™. This patented technology allows users to adapt their laser materials processing solution to match their ever-changing business needs – no tools or special training required. At its core, Rapid Reconfiguration allows users to very simply install and reinstall any ULS laser source onto any ULS laser system. On other laser systems, the task of changing laser sources can be complicated and dangerous and can cause several weeks of downtime

5. Safety & energy efficiency

Safety is a top priority in ULS laser cutting machines. Features such as enclosed cutting chambers, magnetic safety interlock systems, and high quality ventilation systems ensure safe operation. This is especially important in educational settings where users may be less experienced. Many laser cutting machines are designed with energy-saving technologies. This not only reduces operational costs but also aligns with sustainable practices, which is increasingly important in today’s environmentally conscious world.

How to choose the right laser cutting machine

Selecting the right laser depends on your specific needs and budget. Here are some practical tips to help you make an informed decision:

Assess your material needs: Consider the types and thicknesses of materials you will be working with most often. Ensure the machine supports those materials.

Check the working area: The size of the cutting bed determines the maximum size of your projects. Larger beds offer more flexibility but may come at a higher cost.

Look for software compatibility: Make sure the machine’s software is compatible with your design tools and is easy to use.

Consider maintenance and support: Opt for brands that offer reliable customer support, spare parts, and service contracts. This is crucial for minimising downtime.

Budget wisely: While it’s tempting to go for the cheapest option, investing in a quality machine will save money in the long run through better performance and durability.

Supporting your investment

Purchasing a laser is just the beginning. To get the most out of your investment, consider the following:

Regular maintenance: Follow the manufacturer’s guidelines for cleaning and servicing your machine to ensure optimal performance.

Use quality materials: Using laser-friendly materials recommended by the manufacturer can prevent damage and improve cut quality.

Training and resources: Take advantage of training sessions, tutorials, and user communities to enhance your skills and troubleshoot issues.

Service contracts: Having a service contract in place that includes regular maintenance and priority repairs, provides peace of mind.

Embracing Innovation with laser cutting technology

The laser cutting industry continues to innovate, integrating new technologies such as AI-assisted design, improved laser sources, and enhanced automation. These advancements make laser cutting machines more accessible and efficient than ever before.

By choosing a UK-based laser cutter supplier, you are investing in a product that combines cutting-edge technology with local expertise and support. This ensures you have a reliable partner for your creative and educational projects.

Whether you are crafting detailed models, producing educational materials, or exploring new design possibilities, ULS machines provide the tools you need to succeed. Their precision, versatility, and user-friendly features make them an excellent choice for anyone looking to elevate their work.

I hope this helps you understand the key features and benefits of UK-based laser cutting machines. If you want to explore options or need advice on selecting the right machine, feel free to get in touch for more detailed information. Happy cutting!

Comments