How material processing with lasers works

- lucymcnaughton

- Nov 17, 2025

- 4 min read

Updated: Dec 2, 2025

"Laser Material Processing: Unlocking Creativity and Precision"

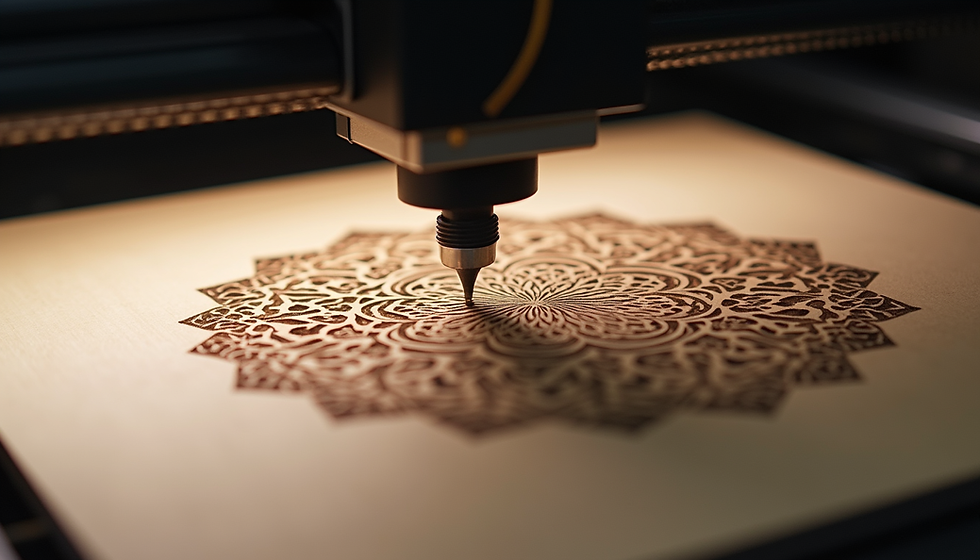

Laser material processing is a fascinating technology that has transformed manufacturing, crafting, and design. As someone who has worked closely with laser cutting and engraving machines, I’m excited to share how this technology works and why it’s so valuable for a wide range of applications. Whether you’re a student, an architect, or a crafter, understanding the basics of laser material processing can open up new creative and practical possibilities.

Understanding Material Processing with Lasers

At its core, laser material processing uses a highly focused beam of light to cut, engrave, or modify materials. The laser beam is generated by exciting atoms in a gain medium, producing a coherent and intense light source. This light is then directed onto the material’s surface, where it interacts in different ways depending on the laser’s power, wavelength, and the material’s properties.

The main types of laser processing include:

Cutting: The laser melts or vaporises material along a precise path, creating clean cuts.

Engraving: The laser removes surface layers to create patterns or text.

Marking: The laser changes the material’s colour or texture without removing material.

Welding: The laser fuses materials together by melting their surfaces.

One of the reasons laser processing is so popular is its precision. The beam can be controlled to micrometre accuracy, allowing for intricate designs and minimal material waste. This precision is especially useful in industries like architecture and crafting, where detail matters.

The Scientific Principles of Laser Material Processing

Laser material processing relies on the interaction between the laser beam and the material’s surface. When the laser light hits the material, its energy is absorbed and converted into heat. This heat causes the material to melt, burn, or vaporise, depending on the laser’s intensity and the material’s thermal properties.

The process involves several key factors:

Laser power: Higher power means more energy delivered, allowing the laser to cut thicker or harder materials.

Wavelength: Different materials absorb different wavelengths better. For example, CO2 lasers (10.6 micrometres) are excellent for cutting organic materials like wood and acrylic, while fibre lasers (around 1 micrometre) work well on metals.

Pulse duration: Pulsed lasers deliver energy in short bursts, reducing heat damage and allowing for fine detail.

Focus spot size: A smaller spot size means higher energy density and finer cuts.

By adjusting these parameters, operators can tailor the laser process to suit specific materials and desired outcomes. For example, engraving delicate patterns on glass requires different settings than cutting thick steel sheets.

Applications of Laser Material Processing

Laser technology is incredibly versatile and used across many fields. Here are some practical examples:

Education and Research: Universities and colleges use laser cutters for prototyping and experiments. Students can create models, circuit boards, and artistic projects with ease.

Crafting and Design: Crafters use laser engraving to personalise gifts, create jewellery, and produce intricate decorations.

Architecture: Architects use laser cutting to produce precise scale models from wood, acrylic, or cardboard.

Manufacturing: Industries rely on laser welding and cutting for automotive parts, electronics, and medical devices.

One of the advantages of laser processing is its ability to work with a wide range of materials, including wood, plastics, metals, glass, and textiles. This flexibility makes it a valuable tool for creative professionals and engineers alike.

Choosing the Right Laser System and Materials

Selecting the right laser system depends on your specific needs. Universal Laser Systems offers a complete range of laser cutting and engraving machines that cater to different applications and budgets. When choosing a system, consider:

Material compatibility: Ensure the laser wavelength matches the materials you plan to work with.

Work area size: Larger work areas allow for bigger projects but may increase machine size and cost.

Power requirements: Higher power lasers can handle thicker materials but may require more maintenance.

Software and Controls: User-friendly software can simplify design and operation, especially for beginners.

In addition to machines, using laser-friendly materials is crucial. Some materials cut or engrave better than others. For example, acrylic is popular for its clean edges and vibrant colours, while certain woods offer beautiful engraving contrast.

To maintain your laser system’s performance, consider service contracts and access to genuine laser parts. This ensures your equipment stays reliable and efficient over time.

Tips for Getting Started with Laser Material Processing

If you’re new to laser material processing, here are some practical tips to help you get started:

Start small: Begin with simple projects to understand how your laser interacts with different materials.

Experiment with settings: Adjust power, speed, and focus to find the best combination for your material.

Use Vector and Raster files: Vector files are ideal for cutting, while raster files work well for engraving.

Safety first: Always follow safety guidelines, including proper ventilation.

Keep materials clean: Dust and debris can affect laser performance and quality.

By following these steps, you can quickly gain confidence and create professional-quality results.

Unlocking Creativity and Precision with Laser Technology

Laser material processing is more than just a manufacturing technique - it’s a gateway to innovation and creativity. Whether you’re crafting personalised gifts, building architectural models, or conducting research, lasers offer unmatched precision and versatility.

If you’re interested in exploring this technology further, I recommend checking out the complete range of laser cutting and engraving machines manufactured by Universal Laser Systems. They also provide an extensive range of laser-friendly materials, parts, and service contracts to support your projects.

Embracing laser material processing can elevate your work, making complex designs achievable and opening new doors for creativity and efficiency.

Conclusion

I hope this overview has given you a clear understanding of how laser material processing works and how you can apply it in your projects. Feel free to explore and experiment - the possibilities are truly endless!

Laser material processing is not just a tool; it's a transformative technology that can enhance your creativity and efficiency. With the right equipment and materials, you can unlock new potential in your projects. So, dive in and discover the amazing world of laser technology!

Comments