Understanding Laser Cutting & Engraving Machines: A Comprehensive Guide

- lucymcnaughton

- Aug 12, 2025

- 2 min read

Updated: Jan 6

What are Laser Cutting & Engraving Machines?

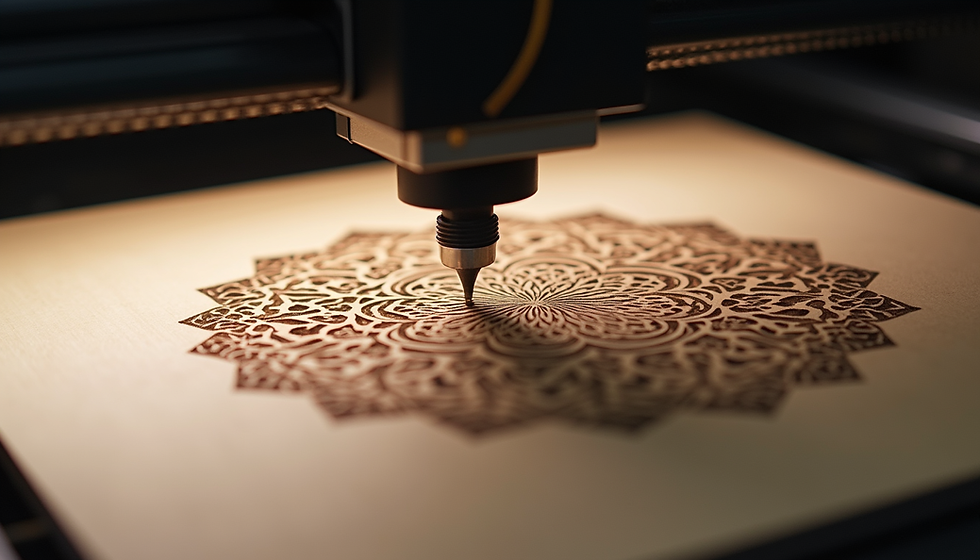

Laser cutting and engraving machines are precision tools that use focused laser beams to cut or engrave materials. These machines work by directing a high-powered laser beam onto a material's surface. This process causes the material to melt, burn, or vaporize. The technology is widely used across various industries due to its accuracy and versatility.

How They Work

The basic operation of laser cutting and engraving machines involves several key steps:

Laser Generation: A laser source generates a concentrated beam of light.

Focusing: The beam is focused through lenses to achieve a small, intense spot on the material.

Material Interaction: The focused laser beam interacts with the material, either cutting through it or engraving its surface.

Control System: A computer-controlled system guides the laser head along predetermined paths to achieve the desired design.

Common Uses of Laser Cutting & Engraving Machines

Laser cutting and engraving machines have a wide range of applications across various industries:

1. Manufacturing

Cutting metal parts for machinery and equipment.

Creating intricate designs in sheet metal.

2. Signage

Producing custom signs and logos from various materials.

Engraving details on plaques and awards.

3. Arts and Crafts

Engraving designs on wood, acrylic, and leather for artistic projects.

Cutting intricate patterns for scrapbooking and other crafts.

4. Prototyping

Creating prototypes for product designs quickly and accurately.

Testing designs before mass production.

5. Jewelry Making

Engraving personalized messages on jewelry items.

Cutting intricate shapes and designs in metal for custom pieces.

6. Aerospace and Automotive

Manufacturing components with precise specifications.

Creating lightweight and complex parts that require exact measurements.

Advantages of Laser Cutting & Engraving

Laser cutting and engraving machines offer several advantages:

Precision: They provide high accuracy, allowing for intricate designs and detailed engravings.

Versatility: These machines can work with a variety of materials, including metals, plastics, wood, and more.

Efficiency: The speed of laser cutting and engraving reduces production time significantly.

Minimal Waste: The precision of the laser reduces material waste compared to traditional cutting methods.

Future Trends in Laser Technology

The future of laser cutting and engraving technology looks promising. Innovations in laser technology are leading to faster processing speeds and improved energy efficiency. Additionally, advancements in software are making it easier to design complex patterns and integrate laser cutting into automated production lines.

As industries continue to evolve, the demand for precision tools like laser cutting and engraving machines will likely increase. This technology will play a crucial role in shaping the future of manufacturing, design, and craftsmanship.

Conclusion

Laser cutting and engraving machines are essential tools in modern manufacturing and design. They offer precision, versatility, and efficiency. Their ability to work with a variety of materials makes them invaluable across multiple industries, from arts and crafts to high-tech manufacturing. If you're considering investing in this technology, it's worth exploring the many possibilities it can offer.

For more information about laser cutting and engraving, feel free to check out this resource.

Comments