The role of precision laser technology

- lucymcnaughton

- Sep 29, 2025

- 4 min read

In today’s fast-paced world, technology is evolving rapidly, and one of the most fascinating advancements is in the field of lasers. Precise laser technology has transformed numerous industries by offering unparalleled accuracy and efficiency. From manufacturing to healthcare, this technology is reshaping how we approach complex tasks. In this post, I’ll share insights into the role of precise laser technology, its benefits, and practical applications that highlight its importance.

Understanding the technology and its impact

Precise laser technology refers to the use of highly controlled laser beams to perform tasks that require extreme accuracy. Unlike traditional tools, lasers can focus on very small areas without causing damage to surrounding materials. This precision makes them ideal for delicate operations.

For example, in the manufacturing sector, lasers are used for cutting, engraving, and welding materials with micron-level accuracy. This reduces waste and improves product quality. In healthcare, lasers assist in surgeries by targeting tissues with minimal invasion, leading to faster recovery times.

The key benefits of precise laser technology include:

High accuracy: Enables detailed work on small or complex components.

Speed: Processes that once took hours can now be completed in minutes.

Versatility: Applicable to metals, plastics, ceramics, and biological tissues.

Reduced contamination: Non-contact nature minimises the risk of contamination.

How precise laser technology enhances manufacturing processes

Manufacturing has been revolutionised by the integration of precise laser technology. Traditional machining methods often involve physical contact, which can lead to wear and tear on tools and materials. Lasers, however, operate without contact, allowing for cleaner cuts and finer details.

One practical example is in the automotive industry. Laser welding is used to join car parts with exceptional strength and minimal distortion. This results in lighter vehicles with improved fuel efficiency. Additionally, laser engraving is used to mark serial numbers and barcodes on components, ensuring traceability.

In electronics, precise laser technology enables the creation of microchips and circuit boards. The ability to etch tiny patterns on silicon wafers is crucial for producing faster and more powerful devices.

To implement laser technology effectively in manufacturing, consider these recommendations:

Invest in high-quality laser systems that offer adjustable power and focus.

Train operators thoroughly to handle laser equipment safely and efficiently.

Integrate laser processes with automation to maximise productivity.

Regularly maintain laser devices to ensure consistent performance.

The role of precise laser technology in medical advancements

The medical field has greatly benefited from the precision and control offered by laser technology. Procedures that once required invasive surgery can now be performed with minimal discomfort and quicker healing times.

For instance, laser eye surgery, such as LASIK, reshapes the cornea to correct vision problems. The precision of the laser ensures that only the targeted area is affected, reducing risks and improving outcomes. Similarly, lasers are used in dermatology to remove skin lesions, tattoos, and wrinkles with minimal scarring.

In dentistry, lasers help in cavity treatment and gum reshaping, offering patients less pain and faster recovery. The ability to sterilise the area during treatment also reduces infection risks.

If you’re considering incorporating laser technology in medical practice, keep these points in mind:

Choose lasers with adjustable wavelengths suited for specific tissues.

Ensure compliance with safety standards to protect patients and staff.

Provide comprehensive training for medical professionals.

Stay updated with the latest research and technological improvements.

Practical applications beyond industry and medicine

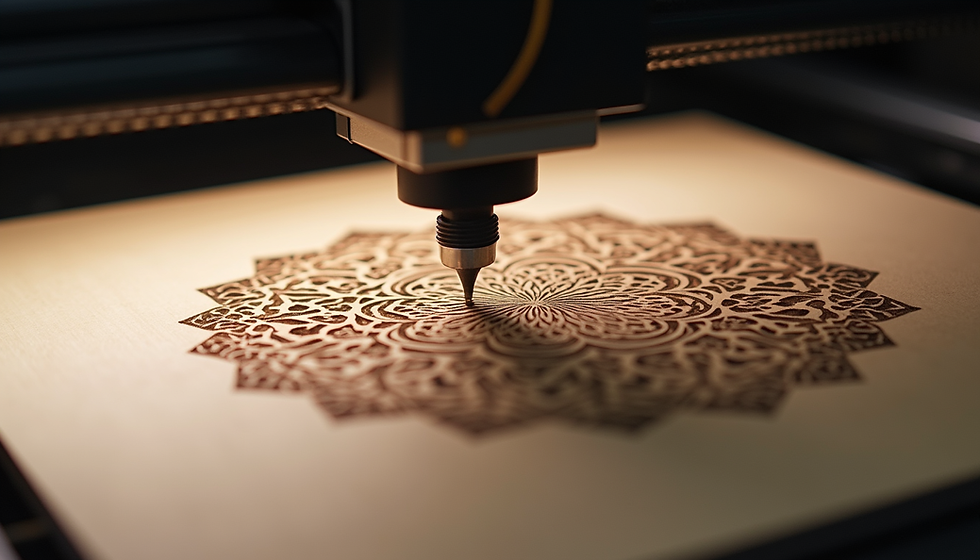

Beyond manufacturing and healthcare, precise laser technology finds applications in many other fields. In the arts, laser engraving allows artists to create intricate designs on wood, glass, and metal. This opens new creative possibilities and customisation options.

In the field of telecommunications, lasers are essential for transmitting data through fibre optic cables. The precision of laser light enables high-speed internet and communication networks that connect the world.

Environmental monitoring also benefits from laser technology. LIDAR (Light Detection and Ranging) uses laser pulses to map terrain and vegetation with great accuracy. This data supports urban planning, forestry management, and disaster response.

For hobbyists and small businesses, desktop laser cutters and engravers are becoming more accessible. These tools allow for prototyping, personalised gifts, and small-scale production with professional results.

Embracing the future with precise laser technology

As technology advances, the role of precise laser technology will only grow. Innovations such as ultrafast lasers and AI integration promise even greater capabilities. These developments will enable new applications and improve existing ones.

To stay ahead, it’s important to:

Keep learning about emerging laser technologies.

Explore partnerships with laser technology providers.

Invest in research and development to tailor solutions.

Promote sustainable practices by minimising waste and energy use.

By embracing precise laser technology, businesses and professionals can enhance quality, efficiency, and innovation in their work.

I hope this overview has given you a clear understanding of how precise laser technology is shaping various industries and what practical steps you can take to benefit from it. Whether you’re in manufacturing, healthcare, or creative fields, this technology offers exciting opportunities to improve precision and productivity.

For more detailed information on the unique features of this technology, you can explore precision laser technology and discover how it can be tailored to your specific needs.

Comments